All the beauty of solid wood without the disadvantages: veneered wood!

Wood is a very beautiful material to work with. The natural look of the material ensures that your project has a high-quality finish. Yet there are disadvantages to working with wood. Fortunately, there are alternative board materials that are not made of solid wood, but still have that beautiful look! In this article, we tell you about melamine faced and veneered wood: chipboard and MDF. Fibreboards with a solid look.

Working with wood

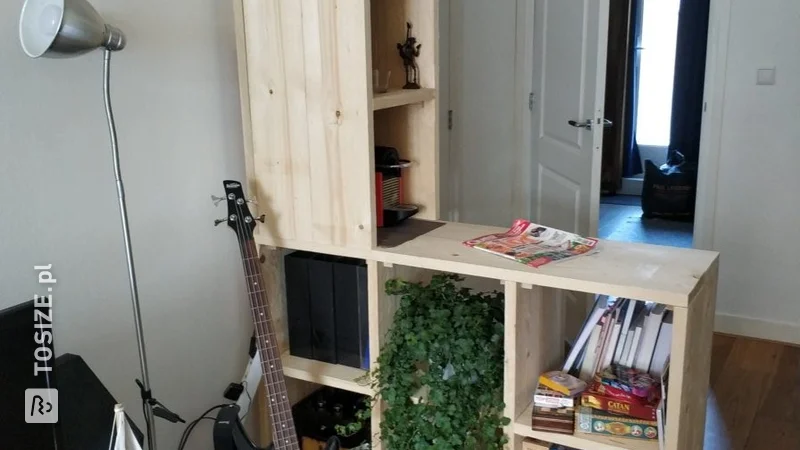

Wood is a commonly used material for decorative projects. You see it in many pieces of furniture, such as cupboards, tables and chairs. Its natural look suits many interior styles, such as Scandinavian, classic, industrial and rural. Working with wood has its advantages and disadvantages, just like any other material. Some of the properties of solid wood can affect the quality of your project, so let's go through them.

The benefits

A major advantage of solid wood is of course its beautiful appearance. Because there are so many different types of wood, you can go in many different directions and there is a suitable type of wood for every application. Wood is also very easy to process. You can easily saw it to size and finish it as you wish. Wood is also a very sustainable material. Because wood comes from a renewable source, the burden on nature is much less than for example with stone or metal. It is important that you buy sustainably harvested wood, which is why all our wood is FSC or PEFC certified.

The disadvantages

Because wood is an organic product, it also has some negative properties. Wood is sensitive to moisture and changing temperatures. The degree of sensitivity varies per wood species, but every wood species has to deal with it. Under these conditions, wood can work, which means that it can shrink, expand or warp. Of course, this is not something you want when you are making furniture, because nobody wants a crooked cabinet door, for example. It is therefore important to finish solid wood by varnishing or painting it.

Alternatives to solid wood

Fortunately, there are alternatives to solid wood that are ideal for making furniture. For example, you have various board materials that are made from multiple pieces of wood such as plywood and lumberboard, but you also have materials that are constructed very differently from solid wood. Examples are melaminated or veneered board materials. These are boards, often MDF or Chipboard, that have a top layer of wood or plastic that looks like wood. The advantage of this? These boards cannot warp! Chipboard and MDF are still sensitive to moisture, but the material cannot warp like wood can. This makes them ideal for making furniture, because you can achieve an extremely tight result with them!

Melamine faced panels

Melamine faced board material is a variant of sheet material, often particle board, that has a plastic top layer. This top layer is made of melamine, and is available in many colours and structures, including many different wood structures. These materials are coloured so that it looks as if it is made of real wood. In addition, the material is also provided with a wood structure, which makes it appear as if it is solid wood with a coating.

View all melamine faced panels

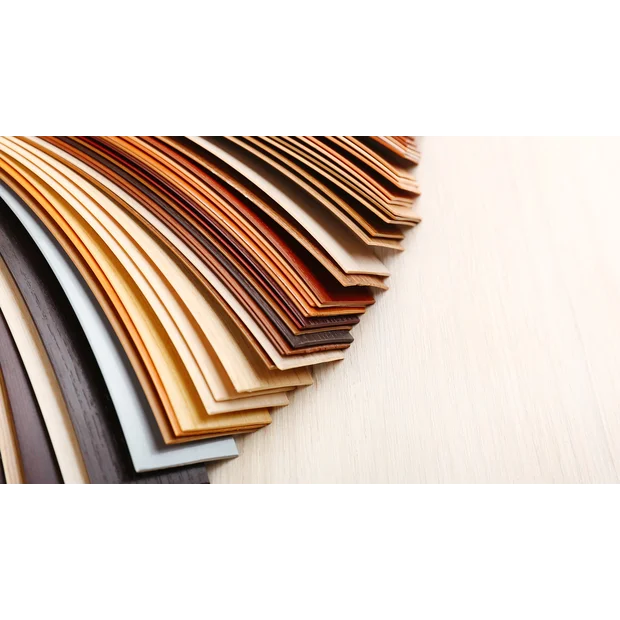

Veneered panels

Veneered panels is actually coated with a layer of wood. These thin layers are better known as wood veneer and are made by peeling thin layers of wood from a tree. So this panel material not only looks like wood, the surface is actually made of wood! This makes the material of slightly higher quality than melamine faced board material and makes it ideal for the more luxurious projects.

Order your material online!

Whether you choose solid wood or these melamine faced and veneered boards, you can always come to us. We have various wooden panels in our range and we also offer many melaminated and veneered board materials. An important part of working with veneered or melamine-coated boards is that the edges still need to be finished. The edges are in fact still visible from a different material than the top layers. Fortunately, we can arrange this for you. When ordering, you can indicate that you want the edges to be finished with ABS tape. We will then ensure that the correct ABS or veneer band is applied to the edges. View our entire range and all possibilities online and start your new job!