- TOSIZE.pl

- Wood and sheet material

- Plywood

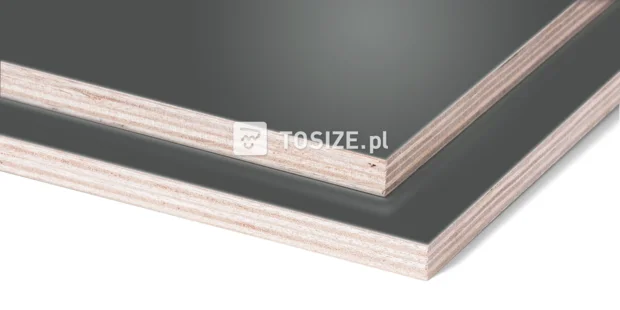

Plywood Marine A/B

Product information

- Especially for use outdoors and in humid areas

- Strong and light sheet material

- Does not bend under heavy loads

- Priming before finishing recommended

Description

Plywood sheets can be used for countless different projects. Plywood marine is the variant that is suitable for outdoor use or in humid areas. This is not only because the sheet is bonded with waterproof glue, but also because the wood species is more resistant to moisture and weather influences. In addition, the wood has a beautiful pink-red colour.

Configure Plywood Marine A/B

How convenient is that

Product information

- Especially for use outdoors and in humid areas

- Strong and light sheet material

- Does not bend under heavy loads

- Priming before finishing recommended

Description

Plywood sheets can be used for countless different projects. Plywood marine is the variant that is suitable for outdoor use or in humid areas. This is not only because the sheet is bonded with waterproof glue, but also because the wood species is more resistant to moisture and weather influences. In addition, the wood has a beautiful pink-red colour.

Product properties

Applications

- Dormers

- Facade cladding

- Doors

- Worktops

Order cut-to-size plywood marine sheets online

Easily order cut-to-size plywood marine sheets online. Plywood can be cut or milled to size into various shapes. The most commonly chosen shape is a rectangle, but we also mill circles, ovals, hexagons or even parallelograms for you. Do you want to have your do-it-yourself project neatly finished? Then choose one of the available (edge) finishes.

Plywood marine: what is it?

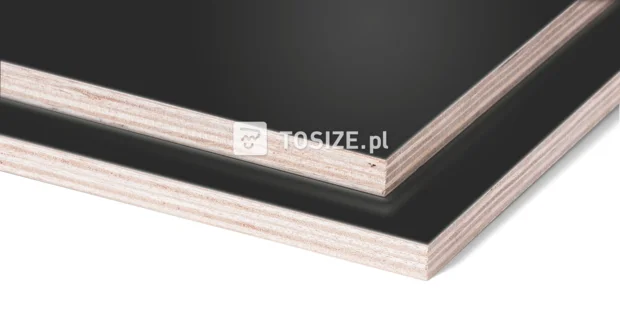

Plywood marine is the plywood variant which is resistant to moisture and is therefore used for outdoor applications or in humid areas. The sheet is, as with plywood birch, bonded with a waterproof glue. Marine is more resistant to moisture, which makes this variant suitable for outdoor applications. But of course you can also choose the sheet because of its beautiful pink-red colour with coarse flames and the fact that it is easy to work with. Plywood is made up of various veneer layers. These layers are glued crosswise on top of each other. This results in a stable sheet. The sheets have an attractive edge that can be used for visual applications.

Plywood quality A/B

The quality of plywood surface layers is indicated by letter combinations and refers to the visual assessment of plywood wood. There is a letter designation for the visible side (top) and one for the reverse side (bottom). It refers to the quality of the deck veneer, the quality of the gluing, for example, is indicated differently. Read more about all visible qualities here.

This board material has visible side A/B. The top side has the visual quality AB, the underside visual quality BB. A plywood panel with view quality B/BB usually has an acceptable visual quality, but does show some imperfections. The front side (the "A" side) has a smooth surface and is free of large knots, cracks and other imperfections. The surface is as uniform as possible. The reverse side (the "B" side) may have colour variations, small knots, repairs and other irregularities, albeit to a limited extent.

This is the highest classification in terms of the visual quality of plywood. This panel material is good for any project. It is important to note that appearance qualities may vary depending on local standards and specifications. When buying plywood, it is advisable to consult the specific ratings and standards of the manufacturer or supplier to ensure that the wood meets the requirements for the intended application.

All in all, plywood A/B offers a balance between functionality and aesthetics, making it a widely used material for a wide range of applications where visible surfaces play an important role.

Available thicknesses of plywood marine

Plywood can be ordered in different thicknesses. You can easily specify your desired thickness during the ordering process. This way you can be sure that the sheet material meets your requirements: both the size and thickness of the material. The following thicknesses are available: 10 mm, 12 mm, 15 mm and 18 mm.

Machining plywood marine sheets

Plywood marine is a hard sheet material type. It is easy to work with when you have sharp tools. For drilling holes, we recommend a wood drill with centring tip. Pre-drilling is also recommended with this sheet material. This sheet material can discolour prematurely, so always finish it with a (clear) varnish, stain or paint. Use an edge sealer to finish the edges of plywood to prevent the lacquer or stain from being absorbed into the sheet material, which can lead to the veneer layers loosening. Are you going to use marine outside? Then it is important to seal the edges with an edge sealer. To be able to enjoy the project outside for a long time, this sheet material still needs protection against humid weather conditions.

Specific applications of plywood marine

Plywood marine is very suitable for projects such as dormers, facade cladding, doors, tabletops and worktops.

Alternatives to plywood marine

Is water-resistant okoumé plywood not the right type of wood for your job or are you looking for a plywood variant that is easy to treat with a varnish or paint and suitable for outdoor use? Then go for multiplex okoumé watervast gegrond. Or check out our other plywood panels below:

Recommended combinations